- HOME

- ROOFING

- METAL ROOFING

- ZINCALUME

- COLORBOND

- CORRUGATED IRON

- NO1 ROOFING ONECORRY™

- NO1 ROOFING 1DECK™

- LYSAGHT CUSTOM ORB®

- LYSAGHT FLATDEK®

- LYSAGHT KLIP-LOK® 700

- LYSAGHT KLIP-LOK® 406

- LYSAGHT LONGLINE® 305

- LYSAGHT SPANDEK®

- LYSAGHT TRIM-KLIP®

- LYSAGHT TRIMDEK®

- STRAMIT CORRUGATED®

- STRAMIT MONOCLAD®

- STRAMIT SPEED DECK®

- STRAMIT® LONGSPAN

- FLASHING

- TRANSLUCENT

- TILE ROOFING

- METAL ROOFING

- ARCHITECTURAL PANELS

- CLADDING

- SKYLIGHTS

- BUILDING

- RAINWATER

- WATERPROOFING

- SAFETY

- SHOP ONLINE

STANDING SEAM | SNAP LOCK | INTERLOCKING | NAIL STRIP | SNAP-LINE 45® | SAVANNA™

The No1 Architectural Panel System range includes Standing Seam, Snap Lock, Interlocking Panels, Snap-Line 45® and Nail Strip.

These standing seam panel system products are available from any of our 10 locations across NSW (7 in Sydney, 1 in Somersby, 1 in Beresfield & 1 in Port Macquarie), and can be supplied in a variety of materials including:

- COLORBOND®

- COLORBOND® Ultra

- COLORBOND® Metallic

- COLORBOND® Matt

- ZINCALUME® Steel

- COPPER, ZINC and ALUMINIUM

SNAP-LINE 45® is a modern, versatile roofing and wall cladding sheet.

The profile has a deep rib height of 45mm and the cover width can be varied from 305 mm to 610 mm.

It is available in various materials such as Colorbond, Zincalume, Zinc, Copper, Aluminium and COR-TEN.

This gives the designer and architect a wide choice of aesthetics to both roofing and walling.

The SNAP-LINE 45® can be rolled on site with a mobile roll former in single, long lengths.

SNAP-LINE 45® has the feature of rolling stiffener ribs and clip relief (optional) into the pan for added rigidity and reducing any dimples that may be caused by the head of the screw with foot traffic pressure.

One of the main advantages of this profile is that it is a structural, self supporting profile that does not require continuous backing (subject to recommended spans and material tensile strengths).

Softer metals such as Zinc and Copper will still require plywood/continuous support under roofing applications.

Material Availability

- 0.55mm BMT Colorbond / Zincalume / Metallic / Ultra

- 0.7mm BMT Copper

- 0.7mm BMT Aluminium

- 0.55mm COR-TEN

- '0.7mm VMZINC, Rheinzink, Zintek Zinc, El Zinc, Jarden Zinc

Installation

SNAP-LINE 45® sheets should be laid into the prevailing wind.

For batten fixing, concealed fixing clips hook over the small rib of the sheet, then fixed down onto the supports within the maximum span recommendations with 10 gauge countersunk screws.

The larger rib on the preceding roof sheet is then snapped and locked down over the small rib and clip.

The edges of the sheets should be fixed for strength and spanning capability.

For optimum finish and softer metals, SNAP-LINE 45® should be installed on a plywood substrate.

The support needs to be ventilated, rigid and continuous where all parts of the panels are laid.

The plywood minimum thickness shall be 12mm – please consult with your building Engineer to confirm the specific Plywood thickness for your project.*

Panels are fixed with concealed clips every 900mm maximum centres. Clips are fixed with 10 gauge countersunk screws onto the timber supports. The small rib is held in place by the clip.

The larger rib is placed over both the clip and small rib then snapped down to create a sealed join.

Material choice to be verified by client and installation must comply in accordance with the BCA. SNAP-LINE 45® is tested and compliant to AS1562.1 as required by current NCC for most building classes.

Although all care is taken in the creation of this document it is only for the purpose of providing information on available profiles.

We strongly recommend you discuss your project with us before selecting these products.

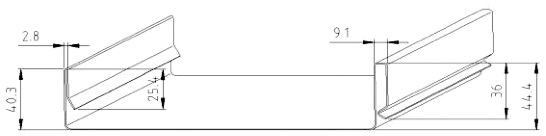

SNAP-LINE 45® Characteristics

|

MODULE SIZES |

45 X 305MM |

45 X 445MM |

|||

|---|---|---|---|---|---|

| Rib Height |

45mm |

||||

| Lengths (Min - Max) |

0.3-15 metres (can be longer depending on site limitations and material choice) |

||||

| Application |

Roofing & Walling for new construction or renovations |

||||

| Minimum Pitch Requirement |

1 Degree |

||||

| Building Standard |

AS 1562.1:2018 |

||||

| Maximum Spans |

Roofing 0.55 BMT Colorbond (mm) (mm) |

Walling 0.55 BMT Colorbond (mm) |

|||

|

End Spans |

600mm |

1800mm |

|||

|

Internal Spans |

900mm |

1800mm |

|||

*Custom widths available upon request.

*Dimensions are subject to -/+ 10mm tolerance.

Check out the full guide on all the different types of standing seam roofs...

GENESIS™ Standing Seam can be used for both facade and roofing applications.

With its thin rib and wide tray, it gives a modern appearance using concealed fixing and crimping techniques to lap panels along entire lengths.

Material Availability

- 0.55mm BMT Colorbond / Zincalume / Metallic / Ultra

- 0.7mm BMT Copper

- 0.7mm BMT Aluminium

- 0.55mm COR-TEN

- '0.7mm 0.7mm VMZINC, Rheinzink, Zintek Zinc, El Zinc, Jarden Zinc

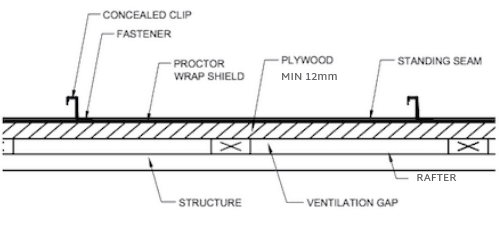

Installation

The support needs to be ventilated, rigid and continuous where all parts of the standing seam panels are laid. The plywood minimum thickness shall be 12mm - please consult with your building Engineer to confirm the specific Plywood thickness for your project.

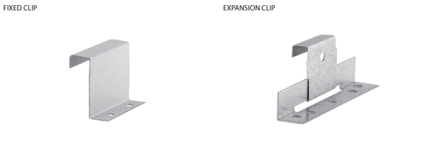

GENESIS™ Standing Seam panels are fixed with steel clips every 600mm maximum centres.

Fixed and sliding clips can be used to allow for expansion and contraction of material.

Clips are fixed with countersunk screws onto the timber supports. Each panel has a male and female rib.

The male rib is held in place by a clip.

The female rib is placed over both the clip and male rib then crimped to create a sealed join.

GENESIS™ Standing Seam can be installed with a single or double seam finished profile.

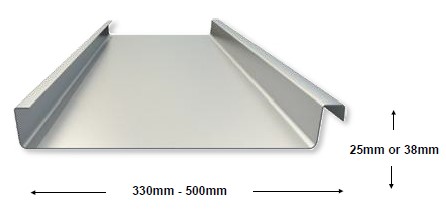

GENESIS™ Standing Seam Characteristics

| Standard Module Sizes | 25 x 330mm | 25 x 530mm | 38 x 300mm | 38 x 500mm |

|---|---|---|---|---|

| Rib Height | 25mm | 25mm | 38mm | 38mm |

| Lengths (Min - Max) | 1 - 8 metres (can be longer depending on site limitations) | |||

| Application | New construction or renovation | |||

| Minimum Pitch Requirement | 3 degrees | |||

| Building Standard | AS 1562.1:2018 Compliant | |||

*Custom widths available upon request.

*Dimensions are subject to -/+ 10mm tolerance.

For more GENESIS™ Standing Seam information, images and Data Sheet downloads - Click Here

ECLIPSE™ Snap Lock is a lightweight cladding system ideal for both roof and wall applications in commercial, industrial and residential environments. Its thin distinctive ribs and wide pans give it visual appeal.

ECLIPSE™ Snap Lock looks similar to Standing Seam without the need of crimping the joints due to the “snapping” process.

Available in 25mm and 38mm ribs, Snap Lock can be manufactured in various widths to suit new construction or renovation projects.

Material Availability

- 0.55mm BMT Colorbond / Zincalume / Metallic / Ultra

- 0.7mm BMT Copper

- 0.7mm BMT Aluminium

- 0.55mm COR-TEN

- '0.7mm Titanium Zinc

Installation

The support needs to be ventilated, rigid and continuous where all parts of the Snap Lock panels are laid.

The plywood minimum thickness shall be 12mm – please consult with your building Engineer to confirm the specific Plywood thickness for your project. Snap Lock panels are laid directly over the ply substrate and held in place with a concealed clip.

Clips are fixed with countersunk screws onto the timber supports at maximum 600mm centres.

Each panel has a male and female rib.

The male rib is held in place by a clip. The female rib is placed over both the clip and female rib.

Material choice to be verified by client and installation must comply in accordance with the BCA.

ECLIPSE™ SNAP LOCK Characteristics

| Standard Module Sizes | 25 x 320mm | 25 x 520mm | 38 x 285mm | 38 x 485mm |

|---|---|---|---|---|

| Rib Height | 25mm | 25mm | 38mm | 38mm |

| Lengths (Min - Max) | 1 - 8 metres (can be longer depending on site limitations) | |||

| Application | New construction or renovation | |||

| Minimum Pitch Requirement | 3 degrees | |||

| Building Standard | AS 1562.1:2018 Compliant | |||

*Custom widths available upon request.

*Dimensions are subject to -/+ 10mm tolerance.

For more ECLIPSE™ Snap Lock information, images and Data Sheet downloads - Click Here

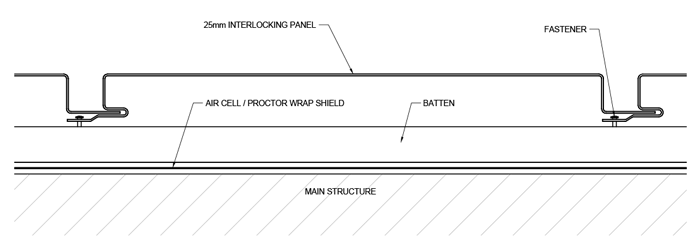

EXPRESSION™ Interlocking panel is a contemporary looking wall cladding system installed with a ventilated air gap for external and internal applications.

The panels are connected by an interlocking groove giving it an elegant appearance of a recessed joint.

The reveal panel can range from 185mm to 385mm in width and lengths up to 6.0 m. Shadow lines can range from 0mm to 25mm.

Material Availability

- '1.0mm 0.7mm VMZINC, Rheinzink, Zintek Zinc, El Zinc, Jarden Zinc

- 0.55mm BMT COLORBOND® / COLORBOND® Ultra / COLORBOND® Metallic / COLORBOND® Matt and ZINCALUME® Steel

- 0.7 BMT Copper

- 0.7 BMT Aluminium

- 0.55 Cor-Ten

Installation

Interlocking panels are laid and fixed down on the grooved flange using concealed fasteners directly onto the batten.

The panels are connected by inserting the male flange into the groove. The load bearing main structure can be a concrete wall, masonry wall or steel.

The batten can be either timber or metal. The battens shall be placed at right angles to the panels.

The panels can be laid horizontally, vertically or diagonally. In the case of non vertical walls, a waterproof membrane must be installed behind the ventilation gap.

Material choice to be verified by client and installation must be in accordance with the BCA.

EXPRESSION™ INTERLOCKING PANEL Characteristics

| STANDARD MODULE SIZES | 25 X 200MM | 25 X 250MM | 25 X 300MM | |

|---|---|---|---|---|

| Maximum Batten Spans | 800mm | 700mm | 600mm | |

| Rib Height | 25mm | 25mm | 25mm | |

| Lengths (Min - Max) |

0.5m to 6.0m (4m recommended) |

|||

| Application |

New construction or renovation on vertical walls |

|||

| Joint Width (Shadow Line) |

0mm to 25mm |

|||

| Building Standard | AS 1562.1:2018 Compliant | |||

*Custom widths available upon request.

*Dimensions are subject to -/+ 10mm tolerance.

Click to view the EXPRESSION™ INTERLOCKING

PANEL Portfolio

No1 Architectural INTERLOCKING

PANEL Wall Cladding Profile

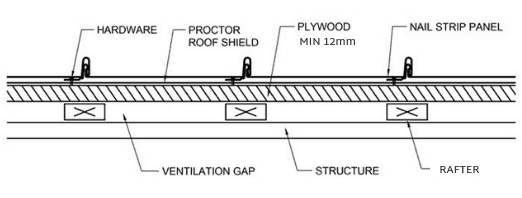

URBANE™ Nail Strip can be used for vertical façade or roofing applications.

Available in 25mm and 38mm rib height, it comes in various widths and lengths to suit your project.

The URBANE™ Nail Strip panel has a thin rib and wide tray with a perforated fixing strip along one side.

There is no need for fixing clips or the additional operation of seaming.

This ensures speed and ease of installing panels whilst allowing for expansion and contraction. It can be used for vertical facade or roofing applications.

Material Availability

- 0.55mm BMT Colorbond / Zincalume / Metallic / Ultra

- 0.7mm BMT Copper

- 0.7mm BMT Aluminium

- '0.7mm Titanium Zinc

Installation

Supports needs to be ventilated, rigid and continuous where all parts of the URBANE™ Nail Strip panels are laid EXCEPT for 38mm x 265mm in 0.55mm BMT COLORBOND® / COLORBOND® Ultra / COLORBOND® Metallic / COLORBOND® Matt and ZINCALUME® Steel which can be installed on a 40mm batten at maximum 600mm centres.

The plywood minimum thickness shall be 12mm – please consult with your building Engineer to confirm the specific Plywood thickness for your project.

URBANE™ Nail Strip panels are laid and fixed directly to the plywood substrate along the perforated strip every 300mm with concealed screws or nails.

The high rib is then placed over the low rib and snapped into place along the length of the panel.

Material choice to be verified by client and installation must be in accordance with the BCA.

URBANE™ NAIL STRIP Characteristics

| STANDARD MODULE SIZES | 25 X 295MM | 25 X 495MM | 38 X 265MM | 38 X 465MM |

|---|---|---|---|---|

| Rib Height | 25mm | 25mm | 38mm | 38mm |

| Lengths (Min - Max) |

1m - 6m (4m recommended) |

|||

| Application |

New construction or renovation |

|||

| Minimum Pitch Requirement |

7.5 Degrees (3 Degrees with lap silicone seal) |

|||

| Building Standard | AS 1562.1:2018 Compliant | |||

*Custom widths available upon request.

*Dimensions are subject to -/+ 10mm tolerance.

Savanna™ architectural wall panels create an aesthetically pleasing, minimalistic look that stands out among steel cladding options.

The overlapping design of these sleek and simple materials is fixed with concealed clips for a clean appearance while also providing superior waterproofing qualities in all types of residential or commercial buildings applications.

Material Availability

Savanna™ comes in a wide range of material options including:

- Colorbond®

- Zincalume®

- Zinc

- Copper

- Aluminium

- Corten

- Uni-Cote® Lux range.

The ability to mix and match materials, sizes and colour choices opens up a whole new horizon of design possibilities.

Installation

Savanna™ is installed over 15mm construction grade plywood with a 20mm air cavity. For roof installation, 17mm construction grade plywood with a 40mm air cavity will be necessary.

You’ll need to lay a moisture-proof membrane or building wrap before installing the Savanna™ panels. Countersunk screws through concealed clips hold the panels securely in place.

The interlocking folds (similar to Inter locking panels) provide an excellent barrier against water intrusion, no matter which orientation they're installed.

SAVANNA™ FLAT LOCK Characteristics

Standard cover widths include:

- 140mm

- 240mm—our most popular size

- 340

- 540

For more Savanna™ Flat Lock information, images and Data Sheet downloads - Click Here

No.1 Architectural Savanna™ Flat Lock

Roofing & Cladding Profile

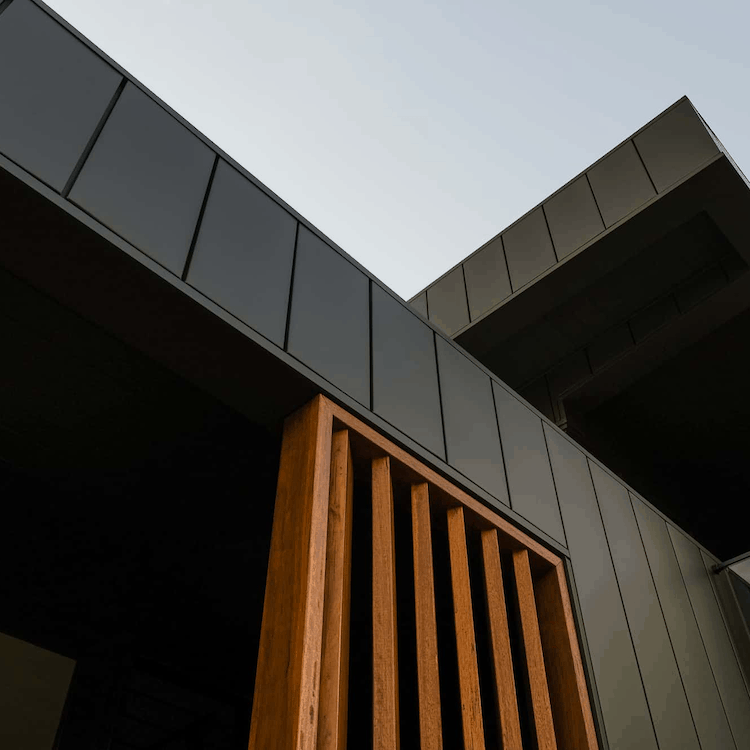

Congratulations DCN Developments on your Standing Seam / Interlocking Panel project in Homebush.

The façade of the apartment block looks amazing and is a standout in the area.

No 1 Roofing & Building Supplies were proud and pleased to have supplied the Interlocking Panels as a wall feature at the entry of the building.

The COLORBOND® Façade was certainly a great choice in colour.

Congratulations to GMA Building on your Nail Strip Standing Seam project in Randwick.

No1 Roofing & Building Supplies were proud to supply the Standing Seam - Nail Strip Facade Panels and Opening Louvre System.

Standing seam panel installation requires some specialised tools including machine tools and some specialised hand tools.

No1 Roofing & Building Supplies carries a huge range of standing seam metal roofing tools including:

No1 Roofing & Building Supplies recommends consulting with your Building Engineer before construction / installation of your standing seam products to confirm the minimum Plywood thickness required for your project.