No1 Roofing Tri-Span™

Introducing No.1 Tri-Span™, the latest innovation in roofing and wall cladding from No.1 Roofing & Building Supplies.

Designed to meet the highest standards of durability, strength, and aesthetic appeal, No.1 Tri-Span™ is set to become a preferred choice for both commercial and residential applications.

Product Navigation

Characteristics and Features

No.1 Tri-Span™ boasts a striking linear profile that combines modern aesthetics with exceptional functionality. Made from high-tensile steel, it offers superior strength and rigidity, ensuring long-lasting performance even in the most demanding environments.

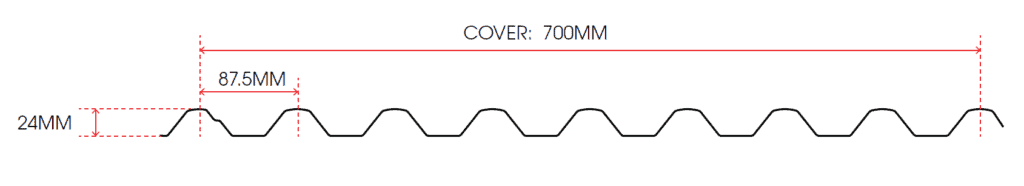

The profile features a wide cover width of 700mm, which allows for quick and efficient installation, reducing labour costs and time on site. Additionally, its ability to span long distances between supports minimises the need for extra structural elements, offering further cost savings.

Additionally, No.1 Tri-Span™ is designed to accommodate roof pitches as low as 2 degrees, making it versatile for various architectural designs.

Benefits

The product's lightweight nature not only makes it easy to handle and install but also reduces the overall load on the building structure, contributing to cost savings in construction.

No.1 Tri-Span™ is made from non-combustible metals meeting the latest building code requirements, providing added safety and peace of mind. Base metal options include the attractive Colorbond® steel range, Zincalume® and Galvanised steel, offering both durability and a variety of colour choices to suit any design preference.

In summary, No.1 Tri-Span™ is a versatile, high-performance roofing and wall cladding solution that combines strength, durability, and aesthetic appeal.

Panel Dimensions

Compliance with National Construction Code

No.1 Tri-Span™ has been extensively tested and is fully compliant and certified to Australian Standards, including testing and certification to AS1562.1. Certificate of Compliance can be provided.

No.1 Tri-Span™ - System Specification

Profile Dimensions:

- Cover Width: 700mm

- Rib Height: 24mm

- Minimum Roof Pitch: 2 degree

Material Specifications:

- Base Metal Thickness (BMT): Available in 0.42mm and 0.48mm

- Steel Grade: High Tensile G550 ZINCALUME® steel

Colour Options:

A wide range of finishes, including all COLORBOND® colours, ZINCALUME®, and GALVANISED steel.

Spanning Ability:

Designed for wide support spacings, reducing the number of purlins required

Water Carrying Capacity:

Excellent, ensuring effective drainage

Non-Combustible:

Meets the latest building code requirements for fire safety

Weather Tightness:

Enhanced by anti-capillary side laps and variable fixing screw patterns

Lightweight:

Easy to handle and install, reducing labour costs and time

Custom Lengths:

Available in custom cut lengths to suit specific project requirements

Packing:

Supplied in strapped bundles of up to 1 tonne for easy transportation and handling

Applications:

- Roofing: Suitable for roof pitches as low as 2 degree, ideal for modern architectural designs

- Wall Cladding: Provides a sleek, contemporary look for both commercial and residential buildings

No.1 Tri-Span™ is engineered to deliver superior performance, durability, and aesthetic appeal, making it an excellent choice for a wide range of building projects. Its innovative design and high-quality materials ensure long-term reliability and value.

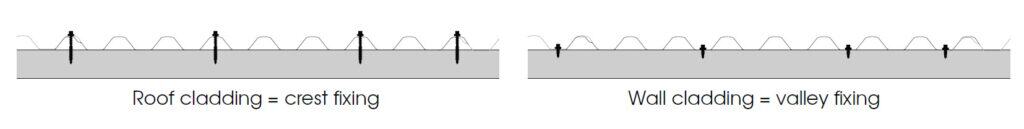

Panel Fixing Details

Recommended Fasteners:

Roof Cladding Fasteners

- Fixing to timber: 6.2 - 13 x 65mm self drilling type 17 hex screws with washer

- Fixing to metal: 6.2 - 13 x 50mm self drilling metal screws with washer

Wall Cladding Fasteners

- 10 - 16 x 16mm self drilling screws with washer

Fixing Spans and Wind Load Resistance

No.1 Tri-Span™ Roof and Wall Cladding (0.42 mm and 0.48 mm)

| BMT (mm) | End Span (mm) | Internal Span (mm) | Strength (kPa) – Roof | Serviceability (kPa) – Roof | Strength (kPa) – Wall |

|---|---|---|---|---|---|

| 0.42 | 900 | 1200 | 4.43 | 1.95 | 5.56 |

| 0.42 | 1200 | 1500 | 3.55 | 1.75 | 4.66 |

| 0.42 | 1500 | 1800 | 2.83 | 1.54 | 3.07 |

| 0.42 | 1800 | 2100 | 2.31 | 1.36 | 2.36 |

| 0.48 | 1500 | 1800 | 3.18 | 1.85 | 3.26 |

| 0.48 | 1800 | 2100 | 3.09 | 1.53 | 2.98 |

| 0.48 | 2100 | 2400 | 2.73 | 1.37 | 2.45 |

| 0.48 | 2400 | 2700 | 2.27 | 1.15 | 2.07 |

Notes:

- It is recommended that a local qualified structural engineer check the suitability of the Ultimate Limit State Design Wind Capacities provided in the load span table for the intended use/structure and site location.

- It is recommended that in the event of an extreme storm/extreme winds the cladding is inspected by a suitably qualified builder/engineer to confirm the adequacy of the cladding and fasteners post event.

- When the product is fixed over a solid substrate, such as plywood, the substrate and its fixings need to be designed to resist the forces induced by internal pressure and not the metal cladding, provided the substrate effectively seals the roof area and the metal cladding is directly fixed to the substrate at its perimeter in addition to the regular fixing system. In this configuration the metal cladding would be required to resist the uplift forces induced by external suction pressures.

Material Handling and Storage

Proper handling and storage of No.1 metal roof and wall cladding products are essential to maintain their quality and longevity. Follow these guidelines to ensure optimal performance:

Storage:

- Store sheet packs undercover and off the ground to protect them from moisture. Use tarpaulins or similar covers to shield the materials from rain and condensation.

- Avoid storing materials in areas where they may be exposed to corrosive environments or chemicals.

- Ensure good ventilation around stored materials to prevent condensation buildup.

Handling:

- Wear clean, dry, cut-resistant gloves when handling steel products to avoid damage to the surface finish.

- Do not drag sheets over rough surfaces or over each other to prevent scratching.

- Carry tools and equipment rather than dragging them across the sheets.

Applicable Australian Standards

Installation of No.1 Tri-Span™ must comply with the following Australian Standards:

- AS 1562.1:2018 - Design and Installation of Sheet Roof and Wall Cladding – Metal

This standard provides guidelines on best practice design and installation techniques for metal roofing and wall cladding, including material quality, fastening techniques, and load-bearing aspects.

- AS 4040.0:1992 - Methods of Testing Sheet Roof and Wall Cladding – Introduction, List of Methods, and General Requirements.

This standard outlines the testing methods for assessing the performance of sheet roof and wall cladding under various conditions.

- SA HB 39:2015 - Installation Code for Metal Roof and Wall Cladding

This handbook provides detailed information on the selection, performance, and installation of metal roof sheeting and wall cladding, ensuring a weatherproof exterior and proper drainage.

By adhering to these standards, you can ensure that your installation meets the required safety, performance, and durability criteria, providing peace of mind and long-term reliability.

Disclaimer

The information provided in this manual is intended as a guide only. No.1 Roofing & Building Supplies does not accept any liability for any loss or damage caused by the use of this information.

It is the responsibility of the installer to ensure that all products are installed in accordance with the relevant Australian Standards and building codes. No.1 Roofing & Building Supplies reserves the right to change product specifications without notice.

Click here for the full product description, specifications and features for NO1 ROOFING Tri-Span™.